| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

İLERİ TEKNİK MAK. SAN. VE TİC. LTD. ŞTİ.

NOSAB GÜRGEN CADDE NO: 4 / NİLÜFER / BURSA / TÜRKİYE

|

Contact Info: +90 224 411 0537

|

Hall: 8

Stand: 811A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

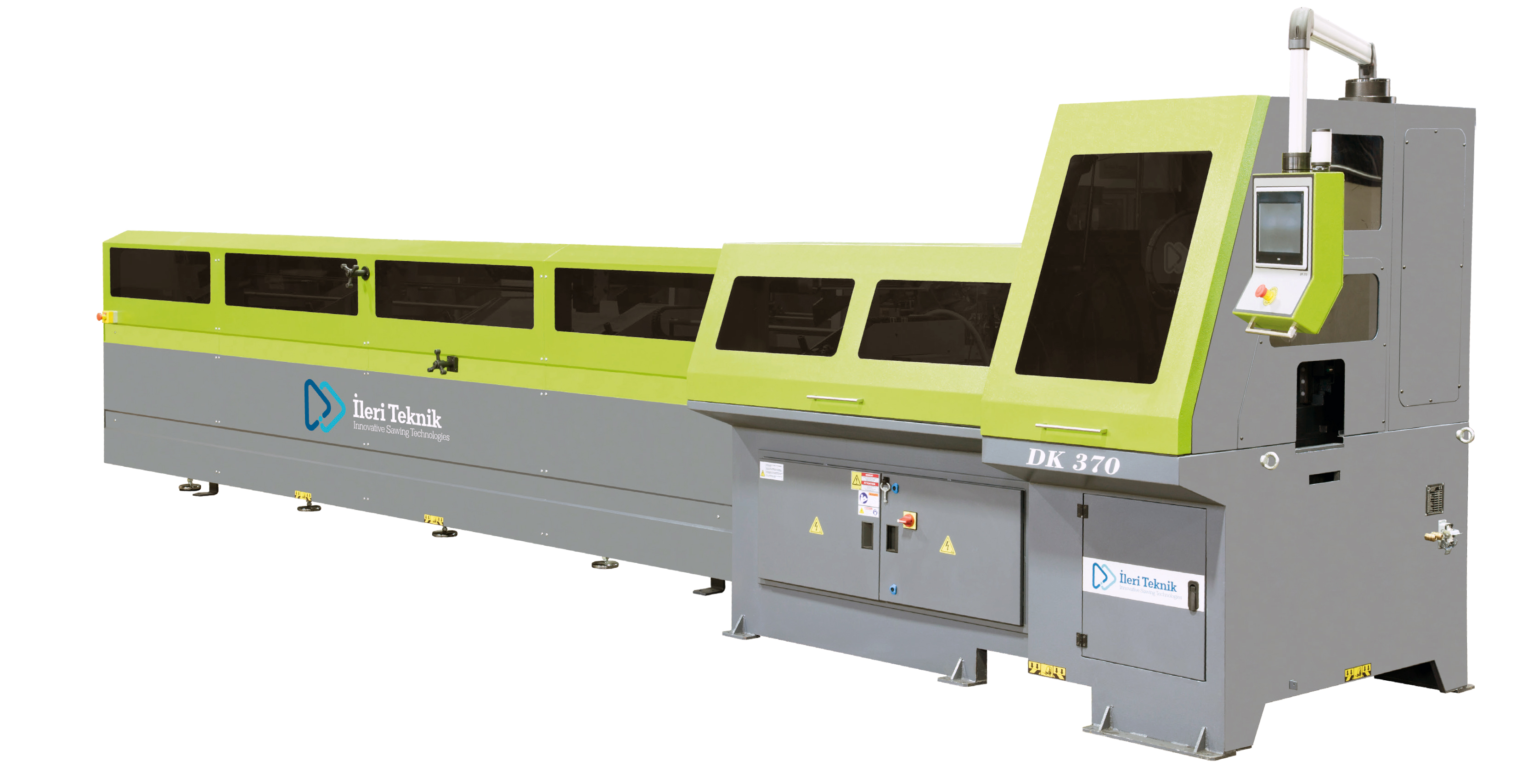

İLERİ TEKNİK was established in 1984 in Bursa/Turkey as a supplier of technical services to the metal and automotive industries. In 1989 started to design and produce Circular Sawing Machines. Nowadays İLERİ TEKNİK producing Fully Automatic cutting lines with automatic loading and unloading systems, semi-automatic and manual cutting machines. İLERİ TEKNİK uses the best materials and very well-known brands during production. Every single part has a quality control procedure and final control check list. All machines are tested before dispatch. Therefore, İLERİ TEKNİK is known as a very good machine builder in all over the world. İLERİ TEKNİK currently export 60% of total products to several countries, which include England, Poland, Holland, France, Belgium, Spain, Norway, Finland, Romania, Bulgaria, Russia, India, South Africa, Israel, UAE, Saudi Arabia and Iran. After sales service engineers located throughout the world, providing a first-class service to operations and key of the İLERİ TEKNİK s ongoing success. İLERİ TEKNİK will continue to design innovative sawing machines and aims to be the market leader.

Fully automatic tube cutting machine with automatic mitre capability Servo motor controlled saw head rotating system up to left and right 60° Servo motor controlled material feeding system with ball screw Servo motor controlled vertical cutting system with ball screw, PLC controlled colour type touch screen display Heavy duty, helical gear and worm gear sets in gearbox Head descends on hardened roller type linear guides, Backlash reduction for prolonged blade life 200 programs to save the all parameters for cutting again the same material. PLC controlled touch screen panel, 20 rpm to 80 rpm blade speed by invertor, 10 different cutting length adjustment in one material ± 0.3 mm cutting length precision for straight cut, ± 0,02 mm machine positioning precision, Coolant tank with box to collect chips and electric pump for blade lubrication and cooling, Micro sprey lubrication system for saw blade Automatic lubrication system for linear guides and rotating head, Optional Accessories: Bundle loading magazine (L=6 mt. / max. Capacity 2.500 Kg) Unloading system(optional 2 mt or 3 mt) , Material support roller Saw Blade

No represented companies found.

The company has no registered brand information.

TR

TR