| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

LİVMAK MAKİNE MÜHENDİSLİK İTH. İHR. SAN. VE TİC. LTD. ŞTİ.

Organize Sanayi Bölgesi 55. Cadde No: 22 / Melikgazi / KAYSERİ / TÜRKİYE

|

Contact Info: +90 352 321 4888

|

Hall: 7

Stand: 721B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Liv Machine has a proud history, which was established in 1979 and completed 43th yearfor the manufacture of pipe bending machines Liv Makina serves the global market with 5 Axis CNC tube bending machines from special and simple equipment for the pipe bending industry to its widest series. Liv Makina designs and serves a variety of products for other leading industrial industries such as furniture, automobile and marine, aerospace and construction. It produces various products such as pipe bending machine, cnc pipe bending machine, double head pipe bending machine for these sectors. Our recently renovated center covers 5000 m²and is equipped with the highest technological production equipment such as CNC machining centers, lathes and milling machines as well as sheet metal cutting and for guaranteed high manufacturing standards. Equipped with tube bending machines. Our products are designed by a team of highly skilled engineers in our technical department - we provide competitive solutions without sacrificing quality. Over the years, it has grown in accordance with our customers requirements and market demand.

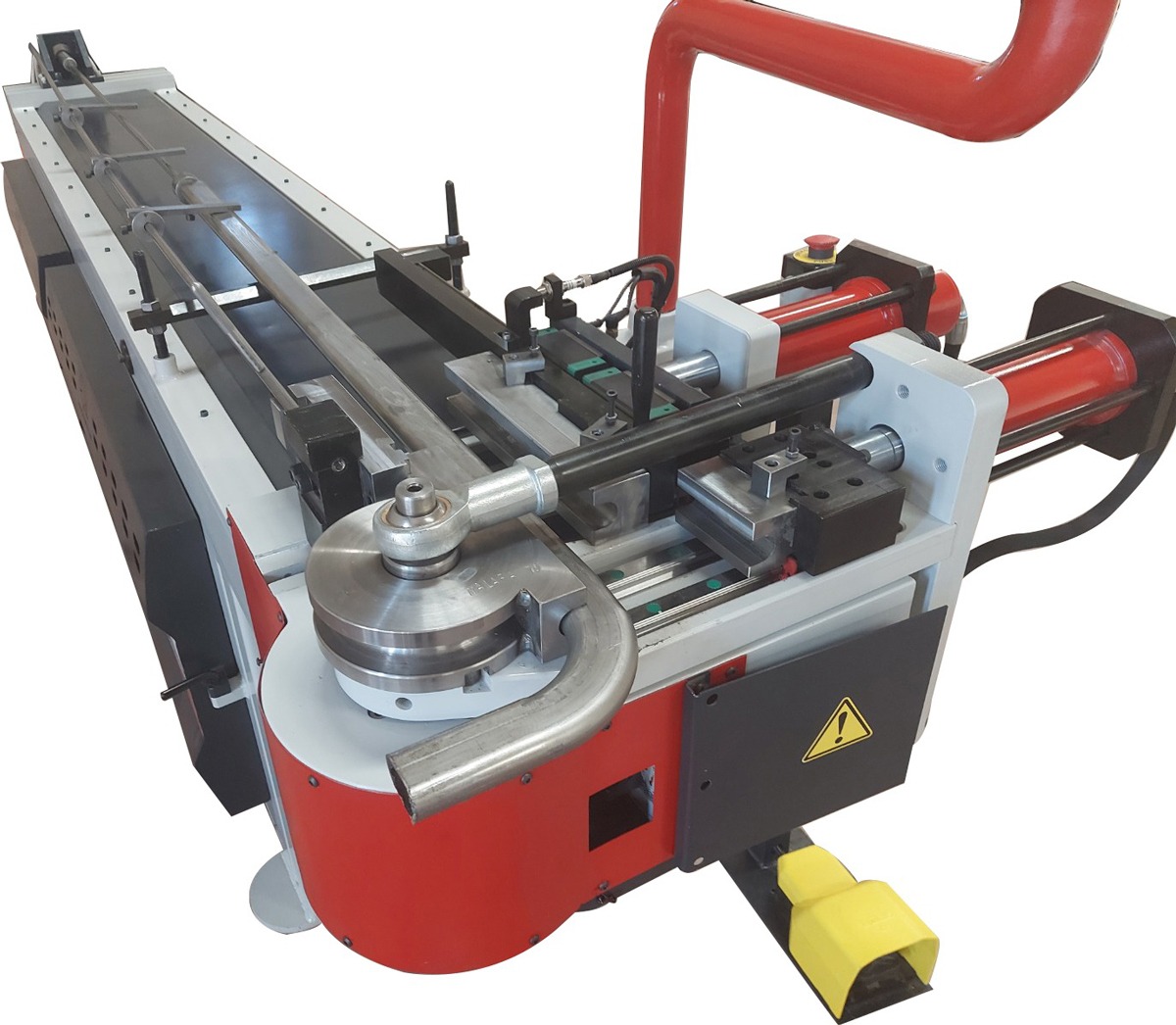

Hydraulic Pipe Bending Machine is a 40-liter hydraulic oil tank with 4HP electric power, which can bend pipes and profiles of various sizes and thicknesses up to 32 mm in diameter and in accordance with the desired diameter / mold dimensions, with the digital display at the desired angles. It is a pipe bending machine without reducer that performs circular movement by transferring the linear motion of the hydraulic piston connected to the other rack to the gear after clamping the pipe with the force it makes to the hydraulic piston mounted on the pipe bending machine with the pump pressure connected to the motor. Maximum bending capacity: 32 x 3 mm Maximum mold diameter: 300 mm Minimum mold diameter: 100 mm Maximum bending angle: 190° Hydraulic clamp Stable bobin Stable mandrel Angle adjustment on digital screen Hydraulic bending system Foot pedal control Able to work with or without mandrel 1 year warranty Complies with CE norms

Maximum bending capacity: 51 x 2.5 mm Maximum die diameter: 300 mm Minimum die diameter: 100 mm Maximum bending angle: 190° Hydraulic Clamp Hydraulic Sledge hydraulic Mandrel PLC Electrical System Touch screen operator panel Being able to see the daily and total production amount on the screen Hydraulic Bending System Foot pedal control Opportunity to work with and without mandrel 1 year warranty Conforms to CE norms

Maximum bending capacity: 65 x 3 mm Maximum mold diameter: 350 mm Minimum mold diamater: 130 mm Maximum bending angle: 190° Hydraulic clamp Hydraulic sledge Hydraulic mandrel PLC electrical systems Touch screen operator control Able to see daily and total production on screen Hydraulic bending system Foot pedal control Able to work with or without mandrel 1 year warranty Complies with CE norms

Maximum bending capacity: 38 x 2 mm Maximum mold diameter: 195 mm Minimum mold diameter: 80 mm Minimum distance between heads: 350 mm Maximum distance between heads: 1950 mm Total bending time: 8 seconds 1 year warranty 7 touch screen Angle deviation +/-1° 100 different product saving to memory Multiple language option Easy mold changing system Complies with CE norms Saving the angles on the screen Able to see Daily production numbers on screen Able to see errors on screen Using in automatic or manuel mode Double or triple mold supply according to pipe size

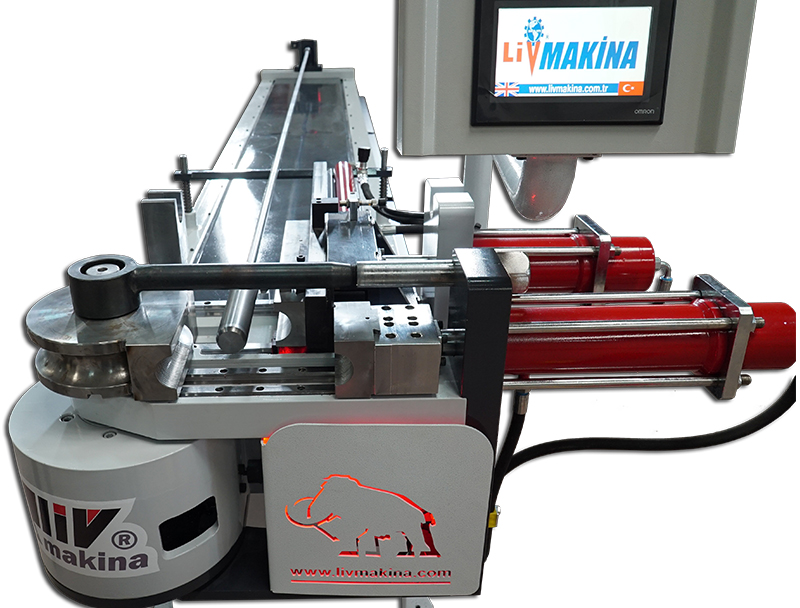

Maximum tubebendingcapacity 42 x 3 mm Maximum molddiameter 300 mm Minimum molddiameter 100 mm Servo rotation, servofeeding, hydraulicbending 3D simulationfeature Automatic bending featurebyonefoottouch Maximum tubehandlinglength (4000 mm) 15 PC touchscreen Abletoseedailyand total bendingquantity Multiplelanguageoption Savingproducttomemory Abletouseautomaticormanualby PLC controlsystem Maximum bendingangle is 190 1 yearwarranty Automatictubelengthcalculation Abletoseeerrors on thescreen Security warningsystem Easytousebysimpleinterface Complieswith CE norms

Maximum tube bending capacity : 65 x 3 mm Maximum bendin Radius: 250 mm Minimum bending Radius: 100 mm Servo rotation, servo feeding, hydraulic bending 3D simulation feature Automatic bending feature by one foot touch Maximum tube length (4000 mm) 15 PC touch screen Able to see daily and total bending quantity Multiple language option Saving product to memory Able to use automatic or manual by PLC control system Maximum bending angle is 190° 1 year warranty Automatic tube length calculation Able to see errors on the screen Security warning system Easy to use by simple interface Complies with CE norms

5 axis CNC tube bending machine; This bending machine is capable of bending pipes from 6 mm to 42 mm and adaptod for usage in too many different industries and sectors. This bending machine is fully automatic for 5 Axis by equpping with all servo systems. This fully automatic bending machine is equipped with touch screen with Windows 10 operating system, 3D simulation and Livmak 3D bending software that is easy to use. Using the machine is so simple and it is proper almost for any kind of application and industrial field. It provides transferring Solidworks, STEP, and IFC file formats via USB and calculates all the axis. The machine automatically adjusts itself for the up,down, right and left bending configuration according to mold size via moving front head. 5 Axis CNC Bending machine is the chine of our tube and profile bending machines. The most important specifications of the machine are durableness, stability and sensitivity even under tough situations such as damp and high temperature. Maximum bending capacity: 42 x 2 mm Maximum mold diameter: 250 mm Minimum mold diameter: 50 mm Direct product drawing transfer with step file Servo bending , feeding , rotation and dimensioning 3D simulation Easy to use by simple interface Able to use 3 molds simultaneously Push bending feature Maximum bending angle is 190° Able to see errors on the screen Security warning system Limitless product saving to memory Tube bending handling length: (5800 mm) Windows 10 Multiple language option 1 year warranty Complies with CE norms

Livmakina s affordable tube bending machines are designed to produce your bending applications reliably and accurately. Our Multi-Axis CNC pipe bending machine provides high quality and high precision in narrow radius and sharp bends. Direct drawing transfer to machine by USB Right and Left bending system Multiple language option 3D Simulation Ability to bend without mandrel Automatic Tube Length Calculation Complies with CE norms Able to see errors on screen Security warning system Easy usage by Livmak simple interface ÖZELLİKLER - SPECIFICATONS LVH MULTI-CNC Maks Büküm Kapasitesi Max Bending Capacity Ø25 mm x 2 mm Min/Maks. Kalıp Çapı Min / Max Mold Size 60/250 mm Malzeme işleme boyu Material Process Length 3500 mm Garanti Ay Warranty (Month) 12 Windows 10 + 15 PC (✓) Büküm Hassasiyeti ± 0,1 Büküm Açısı ± 190 3D Simülasyon 3D Simulation (✓) Servo İlerleme Servo Feeding (✓) Servo Döndürme Servo Rotation (✓)

No represented companies found.

The company has no registered brand information.

TR

TR